Table of Contents

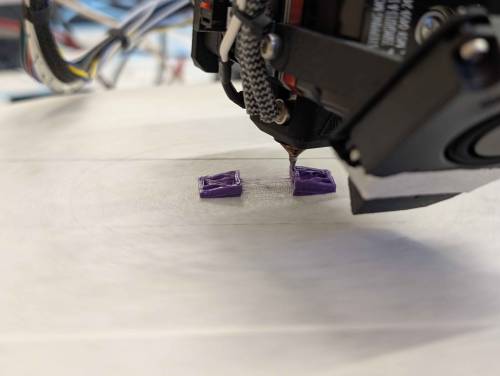

4 Axis Core R Theta 3D printer

Intro

This is an experimental 4 axis non-planar 3D printer originally designed by Joshua Bird for use with his S4 non planar slicer. The original design and firmware has been modified a bit by Zoe and Kate F to make it only slightly less difficult to use. It runs RepRap Firmware on a Fly E3 Ultra mainboard with an ESP32 hosting the web frontend at theta.local.

Getting started

The software side is difficult and annoying and just generally a bit hostile to use - if you want a printer just for normal 3D prints, the Ender 3 is a much tamer beast!

Currently, S4 Slicer runs mostly as a notebook but requires a locally installed copy of Cura with the profile installed. It requires Linux on x86 at the moment but WSL works too. I'm working on a PrusaSlicer profile for it so it can run on Linux on ARM too, as well as a more user friendly version of S4 slicer in a neater package.

Once you've sliced your model and uploaded it, you must first home the printer and manually set the temperature - the slicer won't do it for you. If you're lucky enough to get all the bottom layers down, then you should manually turn on the fan. Don't forget to turn on the MCU fan too to keep the internals cool! This can all be done via the dashboard of Duet Web Control.

The bed is an unheated circle of aluminium that can be adjusted via three thumb screws under it. You will need masking tape covered with glue stick that has been left to dry out to get decent adhesion. It's primitive stuff, but have you seen the price of slip rings?!

To generate a bed mesh for auto levelling, run G32 in the console to run the /sys/bed.g macro.

Quirks

Aside from the obvious, the printer has a few quirks. The biggest unseen one is that, in the firmware, the printer thinks it is cartesian (so instead of it knowing the bed is a circle, it thinks it is a very very very long rectangle - 360mm of movement is 1 rotation). The visual clue for this is the bed mesh being the way it is, instead of a normal circle. If you want to make firmware changes and such, you should keep this in mind.

The part cooling fan is also sub-optimal. It's difficult to get part cooling close to the nozzle when the whole toolhead needs a clearance area around it to avoid bumps when doing non planar prints. If you can work out a way of doing it that doesn't rely on extremely loud air compressors, please implement it!

There's also no spool holder for the filament at the moment.

Working on it

You are more than welcome to work on it and make improvements! If you want to make any changes to the firmware, please make a backup of it first. If you have any questions about it, DM @zoemaestra or @katef on the Discord